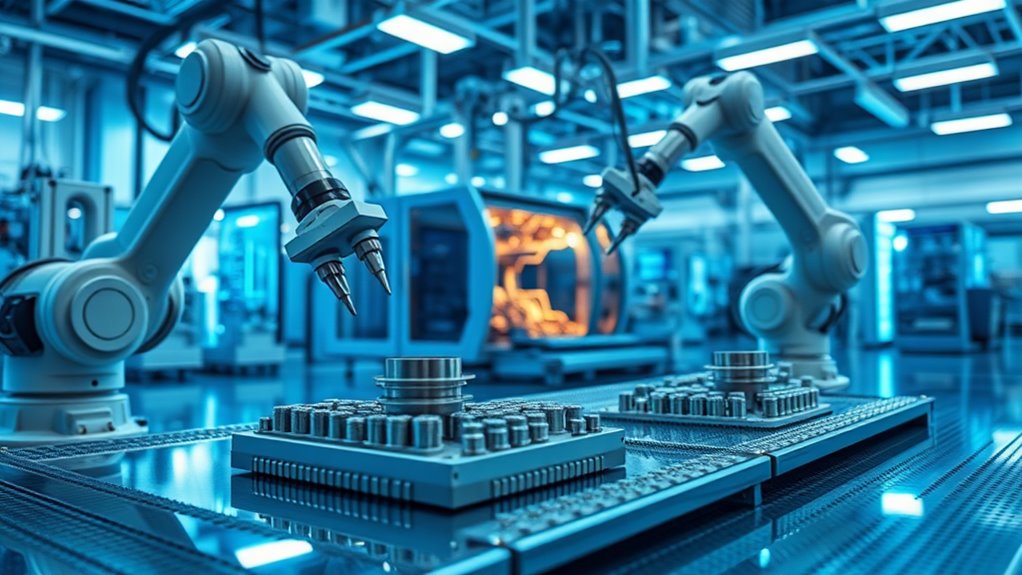

Innovations in precision parts manufacturing today revolve around automation, robotics, and smart manufacturing technologies. Factories are integrating robotics to enhance workflow and reduce human error, while automated systems improve production efficiency and accuracy. Advanced data analytics and smart sensors enable real-time monitoring, optimizing resource utilization. Additionally, AI-driven quality control methods guarantee product consistency. These developments foster flexibility in production and drive continual improvements. Further insights reveal how these innovations reshape the manufacturing landscape.

The Rise of Automation in Manufacturing

The integration of automation into manufacturing processes has transformed the landscape of precision parts production. The implementation of factory robotics and automated assembly systems has markedly increased production efficiencies, reducing lead times and minimizing human error. These advanced robotic systems utilize intricate algorithms and machine learning techniques to optimize workflow, enabling continuous operation at high precision levels. The deployment of automation also facilitates real-time monitoring and data analytics, enhancing decision-making capabilities and predictive maintenance. In addition, automated assembly lines can be reconfigured rapidly to adapt to varying production requirements, providing unparalleled flexibility. As manufacturers embrace these technological advancements, they gain a competitive edge, positioning themselves to respond swiftly to market demands while maintaining stringent quality standards essential for precision components.

Additive Manufacturing: Revolutionizing Design and Production

Additive manufacturing, often referred to as 3D printing, has emerged as a transformative force in the design and production of precision parts, complementing advancements in automation within the manufacturing sector. This technology facilitates significant design flexibility, allowing engineers to create complex geometries that traditional manufacturing methods cannot achieve. By enabling the production of intricate designs and customized components on-demand, additive manufacturing enhances the responsiveness of manufacturing processes. Coupled with advancements in materials science, production speed has remarkably increased, reducing lead times and minimizing material waste. These attributes allow for rapid tooling solutions and iterative design processes, leading to enhanced innovation cycles. Consequently, additive manufacturing is reshaping industry standards, providing manufacturers with strategic advantages in efficiency and product quality.

Robotics: Enhancing Precision and Efficiency

Robotics technology is increasingly pivotal in refining precision parts manufacturing through automation, improving both accuracy and operational efficiency. Collaborative robots are enhancing workflows alongside human workers, streamlining processes while maintaining high standards of safety and productivity. Furthermore, the integration of AI-driven precision control mechanisms is enabling more sophisticated responses to variances in manufacturing conditions, further elevating quality assurance.

Automation in Manufacturing Processes

While manufacturing processes have long relied on traditional methods, the integration of automation through robotics has revolutionized precision parts production. Process automation enables manufacturers to streamline operations, resulting in enhanced accuracy and reduced cycle times. Automated workflows facilitate consistent production output, mitigating human error and variability inherent in manual processes. Robotics not only optimize the physical tasks involved in manufacturing but also integrate seamlessly with advanced data analytics systems, enabling real-time monitoring and adjustments. This synergy enhances operational efficiency, allowing for rapid adaptation to design changes and market demands. Ultimately, the deployment of robotic automation marks a significant advancement in the precision parts manufacturing sector, driving both efficiency and elevated standards of quality throughout the production lifecycle.

Collaborative Robots in Action

The integration of collaborative robots, or cobots, into precision parts manufacturing represents a significant advancement in operational capabilities and productivity. These advanced machines work alongside human operators, enhancing collaborative applications where precision and dexterity are essential. By augmenting the robot workforce with automation, manufacturers can achieve higher efficiency and reduce cycle times in complex machining tasks. Cobots can be programmed to handle repetitive tasks, allowing skilled workers to focus on intricate processes requiring human judgment. This synergy not only increases output but also improves safety in the workplace, as cobots are designed to operate in close proximity to humans without traditional safety barriers. Ultimately, the deployment of cobots ushers in a new paradigm of efficiency and innovation in precision manufacturing environments.

AI-Driven Precision Control

How can the integration of artificial intelligence (AI) elevate precision control in manufacturing? The application of AI-driven algorithms, particularly through machine learning integration, greatly enhances precision machining processes. By analyzing vast datasets, AI systems can identify patterns and make real-time adjustments, leading to improved accuracy in machining operations. This technology facilitates predictive maintenance, ensuring that machinery operates at peak conditions, thereby minimizing downtime and enhancing throughput. Additionally, AI algorithms can refine tool paths dynamically, reducing material waste and cutting times. The synergy between robotics and AI enables manufacturers to achieve unprecedented levels of precision and efficiency, redefining quality standards within the industry. Consequently, AI-driven precision control represents a paradigm shift in the landscape of modern precision parts manufacturing.

Smart Manufacturing Solutions for Real-Time Monitoring

Smart manufacturing solutions have emerged as pivotal tools for enhancing real-time monitoring within precision parts manufacturing. Central to these advancements is smart sensor integration, which facilitates the seamless collection of operational data from machines and processes. These sensors provide vital insights into machine performance, part quality, and environmental conditions, thereby enabling immediate responses to deviations or anomalies. Additionally, cloud monitoring solutions play an essential role by offering scalable data storage and advanced analytics capabilities, enabling manufacturers to access real-time information remotely. This combination of smart sensors and cloud technology not only streamlines monitoring processes but also optimizes resource utilization, leading to increased productivity and reduced downtime. Together, these innovations signify a new era of efficiency in precision parts manufacturing.

Data Analytics: Driving Informed Decision-Making

Data analytics serves as a critical tool in precision parts manufacturing, facilitating real-time performance monitoring to enhance operational efficiency. By implementing predictive maintenance strategies, manufacturers can preemptively address equipment failures, minimizing downtime and associated costs. Additionally, data-driven process optimization allows for continuous improvement in production workflows, ensuring high-quality outputs and resource allocation.

Real-Time Performance Monitoring

As organizations endeavor for efficiency in precision parts manufacturing, the integration of real-time performance monitoring transforms operational decision-making. This approach leverages real-time analytics to capture dynamic performance metrics across production processes. By continuously evaluating key parameters, manufacturers can gain immediate insights, enabling swift identification of inefficiencies and bottlenecks. Such data-driven insights facilitate informed interventions aimed at performance optimization, ensuring that production systems operate at peak effectiveness. Real-time performance monitoring also enhances adaptability by allowing organizations to adjust operational strategies responsively, thereby minimizing downtime and resource wastage. Ultimately, the implementation of real-time analytics not only fosters a more agile manufacturing environment but also supports sustained improvements in product quality and operational throughput.

Predictive Maintenance Strategies

Real-time performance monitoring lays a foundational framework for implementing predictive maintenance strategies, which leverage advanced data analytics to forecast equipment failures before they occur. By integrating sensor technologies, manufacturers can capture critical operational data in real-time, enabling the identification of anomalous patterns that precede failures. This data-driven approach enhances traditional maintenance schedules, shifting from reactive to proactive interventions. Analyzing trends in equipment performance allows for optimized scheduling of maintenance tasks, reducing unplanned downtimes and increasing overall efficiency. Furthermore, predictive algorithms can refine their accuracy over time, utilizing machine learning to improve decision-making processes. Consequently, implementing predictive maintenance strategies guarantees that resources are allocated effectively, ultimately driving significant operational gains in precision parts manufacturing.

Data-Driven Process Optimization

Harnessing analytics for process optimization can greatly enhance operational efficiency in precision parts manufacturing. By leveraging data integration across various systems, manufacturers can implement robust analytics frameworks that facilitate continuous improvement. These frameworks enable real-time insight into performance metrics, allowing for informed decision support. Workflow automation plays an essential role in streamlining operations, directly affecting yield enhancement and resource management. The use of advanced data analytics aids in identifying inefficiencies, subsequently guiding process adjustments. Adopting a data-driven approach not only optimizes current processes but also fosters an environment of perpetual growth. This strategic alignment of analytics with manufacturing objectives reinforces resilience, ultimately leading to superior performance and a competitive advantage in the precision parts sector.

The Role of Artificial Intelligence in Quality Control

While traditional quality control methods often rely on human inspection and manual data analysis, the integration of artificial intelligence (AI) has revolutionized this process in precision parts manufacturing. AI algorithms facilitate real-time quality assessment through advanced machine learning techniques that enhance defect detection capabilities. By leveraging data integration from various stages of production, AI systems can provide extensive insights into process improvement. Additionally, system feedback loops allow for continual optimization, adjusting operational parameters based on performance metrics. This dynamic approach reduces error rates and enhances overall product quality, ensuring consistency and reliability. Consequently, the adoption of AI in quality control is transforming the landscape of precision manufacturing, enabling companies to meet stringent quality standards with unprecedented efficiency.

Frequently Asked Questions

What Are the Environmental Impacts of Precision Parts Manufacturing Innovations?

The environmental impacts of precision parts manufacturing innovations include enhanced sustainable practices and significant waste reduction. These advancements lead to lower energy consumption and diminished resource depletion, fostering an eco-friendly manufacturing landscape while maintaining production efficiency.

How Do Innovations Affect Workforce Training and Skill Requirements?

Innovations necessitate a re-evaluation of workforce training, emphasizing automation techniques and skill adaptability. Workers must acquire competencies in advanced technologies, ensuring they remain proficient and responsive to evolving manufacturing demands and integrated systems.

What Is the Cost of Implementing These Advanced Manufacturing Technologies?

The cost of implementing advanced manufacturing technologies necessitates a thorough technology assessment. Organizations must evaluate the return on investment, weighing initial expenditures against long-term benefits, including productivity boosts and enhanced competitiveness in precision parts manufacturing.

How Do Manufacturers Ensure Cybersecurity in Smart Manufacturing Systems?

Manufacturers implement stringent cybersecurity protocols to protect smart manufacturing systems, emphasizing thorough data protection strategies. These practices include encryption, regular security assessments, and employee training to mitigate vulnerabilities and safeguard critical operational information from cyber threats.

What Industries Benefit Most From Advancements in Precision Parts Manufacturing?

Industries that benefit considerably from advancements in precision parts manufacturing include automotive, which enhances performance through automotive advancements, and aerospace, where streamlined processes and materials improve safety and efficiency in aerospace applications, driving innovation and competitiveness.